Optimal and robust design of P2A systems

One of the approaches considered in the GrAPHy project to deal with the intermittency Hydrogen in Green Ammonia manufacturing processes is via the Power-to-Ammonia (P2A) route. All processes where renewable power act as the main driving force in Ammonia manufacture fit in this class.

The most widely known P2A configuration is that where the Steam Methane Reforming (SMR) unit used in the conventional Haber-Bosch (HB) process is replaced by an electrolyzer unit, and where Hydrogen is produced via the supply of renewable energy. This configuration has been used in the past and still is in a limited number of locations where the regional context favors this route. Currently, it represents an outlier in the context of global Ammonia manufacture, since the HB process generally offers the cheapest route and is the predominant industrial process in this context.

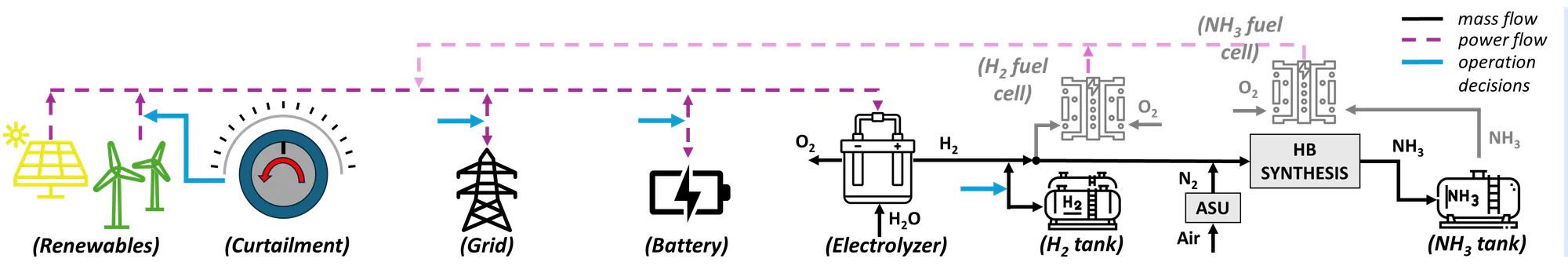

This approach expands the typical envelope of relevant units in process design and operation from the actual manufacturing units, to include also the complex operations involved in power harnessing and management. Since renewable power fluctuates in time and cannot be exactly predicted, this concept brings significant challenges on how these systems should be designed and operated. This includes power curtailment, grid power exchange and the management of buffer units (batteries and hydrogen tanks), as depicted in Figure (P2A architecture).

P2A architecture.

Time becomes a critical variable in the design of these systems, where a single optimal design at steady-state conditions is no longer applicable. In fact, design typically considers the load factors of renewable sources over a full year of operation in intervals of 1h, which significantly increases design complexity. In the GrAPHy project it is our goal to design novel methods for the design and operation of these systems.